GENERAL

- Decor Cabinet Company uses high quality coatings for all finishes.

- Solid wood, wood veneers, and high-density fiberboard (HDF) are all materials that are cut and machined to order specifications in preparation for sanding.

- All products go through a meticulous final sanding process and inspection before the finishing process.

- All finished products go through a final inspection stage at the end of the finishing process.

- All finishes over time will age. With aging comes changes in colour and durability.

- When you have a 5-piece front, the finish may look one colour when you have the front sitting vertical. Then, when turned horizontally, it may look like a different shade of the same finish. This is due to how light hits the grain of the front.

WOOD CHARACTERISTICS

- Decor Cabinet Company uses high quality kiln-dried hardwoods.

- There are hundreds of varieties of hardwood trees including, cherry, oak, maple, walnut, and alder species. Hardwoods are from trees that have broad leaves and produce a fruit or nut and go dormant in the winter months.

- Each type of wood species has its own individual cell structure and unique physical properties that lend themselves to every kitchen project.

- All wood species have some common characteristics, such as pin knots, knots, burls, streaks, spots, bark pockets, worm tracks, vine marks, cross bars, ray fleck, colour variations, sapwood, heartwood, etc. All of which are normal and should be expected.

- Some wood species have extra characteristics that are not as common in other species such as:

- gum spots in cherry.

- Birds eye in maple

- Large colour and grain variance in white rift oak

- Etc.

- The term heartwood refers to old growth of the tree, which is, in most cases, typically and significantly different in colour than the sapwood which is new growth.

- All wood ages naturally whether finished or unfinished light exposure affects all wood species over time. Some species will darken with age where others will get lighter. This is normal and should be expected.

- Hardwoods used in kitchen cabinets are selected for a variety of properties such as density, durability, machinability, individual unique characteristics such as colour, texture, cell structures, and grain patterns.

- The differences in the colour, grain patterns and characteristics adds to the natural beauty of solid woods and veneers.

- The number of characteristics allowed in any given species for manufacturing is determined by the type of cut and grade of material.

STAIN COLOUR FINISHES

- Depending on the colour and substrate, some stain colours are wiping stain only whereas others are a combination of a toner and a wiping stain.

- For some colours, sprayers apply a toner to add more depth in the colour and provide a more uniformity that would not be possible with only a wiping stain.

- Toners assist in blending the natural colour variation in solid wood and veneers.

- With the exception of a desired natural finish, all stain colours, including those using a toner, a wiping stain sprayed on to the substrate and hand wiped, are worked into the wood to create depth and bring out the natural beauty of the wood and grain.

- A coat of premium quality post-catalyzed vinyl sanding sealer is sprayed onto the colour to protect it and promote superior adhesion of the entire finish system.

- The sealer is baked in an oven, allowed to cool down, then hand scuffed smooth with a high-quality fine grit sandpaper. Then the product is given a final overall inspection prior to receiving a glaze or the final clear coat application.

- If an optional glaze is picked, it is applied after a sealer sanding is done by hand, then allowed to dry.

- To provide beauty, protection, and durability to your cabinets, a healthy coat of post-catalyzed clear conversion varnish is applied as the final coat.

IMPORTANT NOTE ABOUT STAIN COLOUR FINISHES

- Lighter colour stains will highlight grain variations more than a darker finish, including the fletches and sections of the material. This may cause the finish to look inconsistent within the same front, but this is what you would expect from the characteristic of the wood and the light colour stain that has been chosen. Warranty would not be considered due to the characteristics of the type of wood and finish chosen.

- Veneers and solid wood materials will have a different consistency from the finish.

- This applies to veneer door styles, end panels, center panels, etc.

PAINT COLOUR FINISHES

- Decor Cabinet Company offers a wide range of standard paint colours as well as custom paint colours.

- Standard paint colours also have glazes and glaze technique options to choose from.

- The standard process for paints is a two-coat system.

- First, a coat of premium quality, post-catalyzed opaque enamel primer is applied to the substrate offering excellent durability and flexibility, as well as promoting adhesion of the entire finish system.

- The primer coat is baked in an oven, allowed to cool, then scuff sanded smooth in preparation for the paint coat.

- The final paint coat is a premium quality two-component solid colour (paint) topcoat.

- For paint with glaze there are a couple additional steps.

- The paint coat is lightly scuff sanded with fine grit high quality sandpaper.

- The glaze is sprayed on, then wiped or hand brushed, depending on the technique selected.

- The glaze is allowed to dry in preparation for the final coat.

- The last step on a paint with glaze finish is a coat of post-catalyzed clear conversion varnish.

WOOD SPECIES

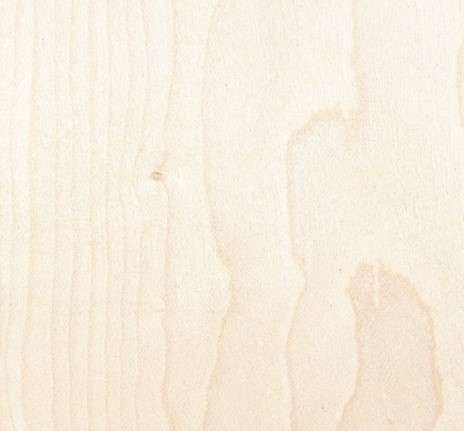

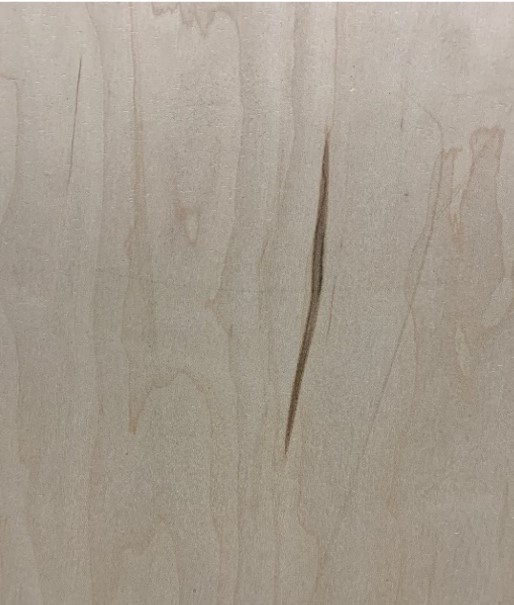

Maple

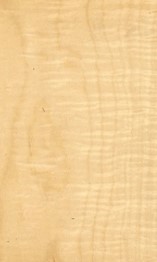

Maple is known for its dense cell structure, smooth, fine grain pattern and overall colour consistency. Maple is creamy white in colour compared to other hardwoods. It is our most common substrate for finishing. Common characteristics in maple are dark mineral streaks (ranging from black to greenish brown), pin knots, burls, and the occasional cross bars or bird’s eye pattern. Some of these characteristics, due to their patterns when finished, will reflect light differently and may be more visible.

No two pieces of wood are alike There is some slight colour variation in maple. Some stain colours can have a more distinct mottled or blotchy appearance because maple has a smooth dense surface. All stain colour finishes in maple use a toner as the first step to assist in reducing the blotchiness of colour applied to the substrate along with evening out material colour variation as much as possible. Some stain colours however will highlight the variation while others will blend them. Typically, a lighter stain colour will show more variation where a darker stain colour will blend them closer together. Maple is excellent to machine; it is easily sanded and stained for a fine, smooth and durable finish. Although maple can be painted, it is NOT recommended. Painted joints on maple will show gap over time. Decor prefers and encourages all painted doors to be HDF.

Acceptable Defects by Finish on Maple

Mineral Streaks

All Stain – On Back

Paint – Yes

Sap Stain

Standard Stain – On Back

Exception: Natural – No

Urban Stain – No

Heritage Stain – On Back Paint – Yes

Heartwood

(Dark Brown Wood)

All Stain – No

Paint – Yes

Crossbars

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Heritage Stain – Yes

Paint – Yes

Pin Knots

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Heritage Stain – Yes

Paint – Yes

Crossbars

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Heritage Stain – Yes

Paint – Yes

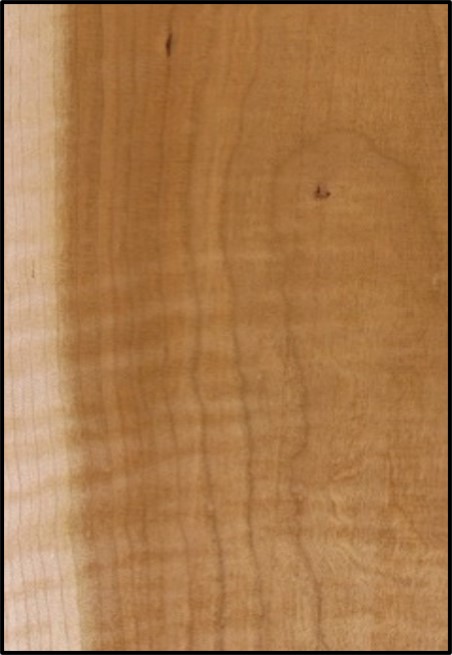

Cherry

Cherry is of medium density, has a straight grain, a smooth, fine, uniform texture and warm colour tones. It is easy to machine and, when sanded and stained, it produces an excellent smooth finish. Cherry can vary significantly in overall colour. Decor primarily uses the heartwood variety of cherry, which is the older growth of the tree where the colour can range from a rich reddish-brown to greenish brown colour. Sapwood in cherry, on the other hand, is a creamy white which is high in contrast to heartwood. In the manufacturing process there are steps to remove any sapwood and blend the overall colour of components.

Cherry wood is a more photosensitive wood than most hardwoods, meaning it darkens over time with exposure to light. This can show sooner on lighter stain colours than darker ones. Like most hardwoods, cherry will contain small pin knots and burls. A unique characteristic to cherry is known as gum spots along with the associated small dark longitudinal streaks. These dark streaks can extend for several inches. Gum spots can be small or large, sometimes following the full growth ring around a tree. All these characteristics of cherry wood make it a unique wood species with rich colour, and excellent machining and finishing qualities that culminate to create elegant kitchen cabinets.

Acceptable Defects by Finish on Cherry

Sapwood

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Coastal Stain – Yes

Pin Knot Cluster

Standard Stain – No

Urban Stain – No

Coastal Stain – Yes

Pin Knots

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Coastal Stain – Yes

Sap Marks

Standard Stain – Yes

Exception: Natural – No

Urban Stain – No

Coastal Stain – Yes

Mineral Streak

Standard Stain – On Back

Exception: Natural – No

Urban Stain – No

Coastal Stain – Yes

Gum streaks or spots

All Stain – Yes

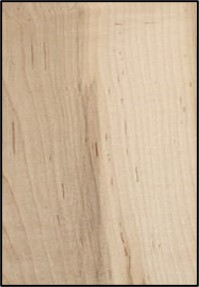

Walnut

Walnut wood is dark, hard, strong, dense, tight grained and resilient. It resists warping and suffers little shrinkage while not being excessively heavy. The grain is typically straight with a medium texture but can have some irregularities. The end grain is semi-porous with distinct growth rings. Walnut has a distinct transition from heart wood – which is a dark chocolate or coffee colour – to sapwood that can be yellowish to creamy white. In the manufacturing process there are steps to remove any sapwood and blend the overall colour of components. Typically, walnut is straight grained but can have some figured grain patterns such as curl, crotch, burl, and small pin knots.

As cherry wood darkens with age, walnut behaves the opposite way. UV Light exposure on walnut over time will lighten the dark wood. Walnut has excellent woodworking qualities while able to be sanded to a smooth finish. It is an ideal wood for stains and clear finishes. Walnut is prized by woodworkers for making fine furniture and cabinetry.

Acceptable Defects by Finish on Walnut

Sap Wood

Standard Stain – No

Urban Stain– No

Coastal Stain – Yes

Pin Knots

All Stain – Yes

Clear Alder

Knotty Alder

Clear and Knotty Alder

Alder is considered a hard wood of medium density. Even though it is a hardwood it is softer than most. Alder is sometimes referred to as a semi- hardwood. It will dent more easily but is still considered durable and a good choice for cabinetry.

Clear alder will have minimal pin knots and burls and has an evenly textured grain pattern like cherry. It has a uniform small pore structure with a consistency in colour. The colour is light yellowish brown with reddish undertones, and indistinct boundaries between heartwood and sapwood.

Knotty alder will have both sound and unsound knots, pin knots, burls as well as some cracked and partially open knots. Knots distract you from the rest of the material making it possibly appear different in colour.

Alder stain colour systems (except for natural) have a toner and wiping stain process. The toner assists in keeping the stain even allowing for a consistent, uniform colour. Both species of alder are great for various distressing techniques to provide a rustic or antique look. The veneer skins are so thin that sound knots are not always possible. In these instances, knots will have putty applied to create a sound surface for sanding and finishing.

Acceptable Defects by Finish on Clear Alder

Pin Knots

All Stain – Yes

Cracks

All Stain – No

Open Knots

All Stain – No

Closed Knots

(Dime Size)

All Stain – Yes

Pin Knots on Edges

Standard Stain – Yes

Exceptions: Cottage Colours – No

Natural – No

Heritage Stain – Yes

Coastal Stain – No

Rough Grain

All Stain – No

Acceptable Defects by Finish on Knotty Alder

Knots

(Loose, See Thru, on Edge of Board)

All Stain – No

Knots

(Loose, See Thru, on Edge of Board)

All Stain – No

Open Knots

All Stain – No

Knots

All Stain – Yes

Oak

Oak wood is hard, stable, heavy, durable, and exceedingly strong. It is a porous open grained wood, mostly straight with cathedral arches and a coarse texture grain. The heartwood is a pinkish-reddish brown, while the sapwood is a light to medium brown with a reddish hew. Oak has indistinct boundaries between heartwood and sapwood. As with all wood, oak will contain characteristics such as small pin knots, burls, and mineral streaks. In the manufacturing process there are steps to blend the overall colour of components. Oak is easy to finish since it has none of the blotching problems that are associated with some hardwoods. The open pores absorb more stain, so the grain pattern becomes quite evident when applied. Oak provides an attractive finish on fine furniture and kitchen cabinets.

Acceptable Defects by Finish on Oak

Mineral Streak

Standard Stain – No

Urban Stain – No

Coastal Stain – Yes

Pin Knots

All Stain – Yes

Sap Wood (White)

Standard Stain – On Back

Exception: Natural – No

Urban Stain – No

Coastal Stain – Yes

White Rift Oak

Rift oak is a hard, heavy, strong, and durable wood. White rift cut oak has heartwood that is a light to medium brown with an olive cast. Sapwood for rift oak is white to light brown and is not always sharply discernable from the heartwood. The term rift cut refers to boards cut from timber with the grains intersecting the face of the board at an approximate 60-degree angle. This cut produces boards where the grain pattern is tight and consistent and where the stability of each plank is greatest. It either has a straight or mildly curved grain pattern. Rift oak will have that same straight or mildly curved uniform grain on the top and bottom and will also have nice parallel grain on the two edges. Rift sawn lumber produces an almost straight grain with little to no flake or figure. Rift cut will provide more consistent patterns throughout the project design. This wood also produces vast colour variation with certain stain colours.

Acceptable Defects by Finish on White Rift Oak

Ray Flake

Standard Stain – Back Only

Exception: Natural – No

Urban Stain – No

Coastal Stain – Back Only

Check/Cracks

All Stain – No

HDF

High Density Fiberboard (HDF) is an engineered wood product composed of wood fibers extracted from wood chips and pulped wood remnant. It is formed with glue while under immense pressure and heat. The recycled nature of its construction makes it environmentally friendly. HDF is a denser, stronger, and more durable material than Medium Density Fiberboard (MDF). HDF does not contract or expand with heat and is dimensionally stable and is more water- resistant than MDF. Its uniform texture, density, and smoothness make it an ideal material for painted finishes. You can order any of Decor’s standard paint colours or custom paint colours in HDF for beautifully finished cabinetry

Engineered Veneers

Engineered wood veneers (recomposed, reconstituted, exotic, or man-made) are intentionally manufactured to achieve specific aesthetic qualities. Wood fibres, resins, and other materials are processed to replicate the appearance of natural wood.

A primary advantage of engineered wood veneers is their consistency. They are designed to have a uniform color, grain pattern, and texture. This is especially valuable for large-scale projects or when matching veneers across multiple surfaces. Manufacturers can control and adjust the veneer’s appearance, creating specific colours, grain patterns, and finishes, for a custom appearance.

Engineered products are more widely available than some exotic or rare wood species, allowing designers to achieve the look of expensive or scarce wood types without depleting natural resources. They are often made from fast-growing species or wood fibres from sustainable sources, reducing the demand for slower-growing or rare trees. This can make engineered veneers a more environmentally responsible choice.

These durable materials are also less prone to splitting, warping, or cracking than some natural wood veneers. This makes them suitable for environments with fluctuating humidity and temperature. Overall, engineered veneers are a modern, cost-effective material that provides a high-end appearance.

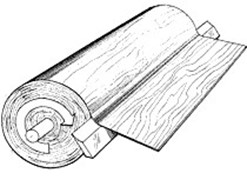

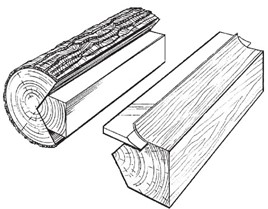

Wood Veneers

A wood veneer is made up of a thin layer of natural hardwood that is then bonded to a stable composite base material such as plywood, particle board, and MDF. The purpose of a veneer is that it’s more affordable than solid timber as less actual wood is used, while the base material gives the veneer overall stability. There is a variety of different methods used to create veneer skins. These are just a few of them.

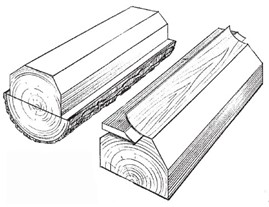

VENEER CUTTING METHODS

Rotary Peeling

Rotary peeling is like unwinding a roll of paper. The log is turned in a lathe against a razor-sharp blade. The cut follows the logs annular growth rings that produces a broad grain pattern. Rotary veneer is very wide. The entire length of the log is peeled and can yield full sheets of veneer and is also cut into leaves for other types of matching. The grain pattern is broad without the appearance of plain or quarter slicing.

Plain Slicing

Plain slicing is done with the log mounted with the heart side flat against the slicer table. Slicing is parallel to a line through the center of the log. This is the most common method of slicing veneers. The result is a combination of cathedral grain and straight grain patterns with some that are quarter in appearance.

Quarter Slicing

Quarter slicing is when the cut is perpendicular to the growth rings of the log. This produces a straight grain appearance. This may also produce what is called ray flake in red and white oak. Quarter slicing produces narrower components than the plain slicing method. Quarter slicing yields less veneer than plain slicing.

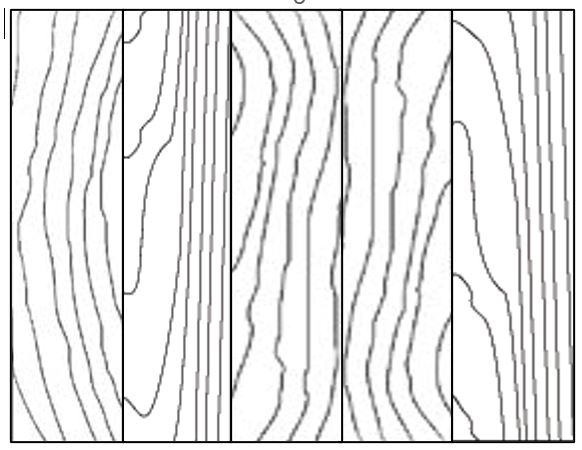

Book Matching

This is the most common type of matching. Every other leaf of veneer is turned over much like the pages of a book. The meeting edges produce a symmetrical pattern. Matching joints with maximum continuity of grain. This can be used with either plain or quarter-sliced veneers. Any wood characteristics such as pin knots, mineral streaks, gum, burls, worm tracks, etc., within the panel will appear as a repeat pattern. Veneer flitches are the same specified width across the sheet, yet the width of flitches may vary sheet to sheet. The barber pole effect may occur due to the tight and loose cut faces alternating. Adjacent pieces of veneer may take stain and reflect light differently which may result in a noticeable colour variation.

Slip Matching

Veneer leaves are fed out in sequence. Leaves are joined side by side, rather than flipped as in book matching. This method results in a repetition of the grain figure but with non-matching joints. Leaves are typically the same width across the sheet. The result is a panel which displays the maximum colour uniformity and is commonly used with quartered and rift-sliced veneers. Any characteristics such as pin knots, mineral streaks, gum, burls, worm tracks, etc., within the panel will appear as a repeat pattern. Veneer leaves are the same specified width across the sheet. The width of flitches may vary sheet to sheet.

Pleasing Matching

Veneer leaves are matched by colour similarity. This type of matching provides an overall pleasing appearance. Leaves are the same specified width but vary sheet to sheet. No sharp colour contrasts are allowed at the joints. Grain characteristics may or may not match. A pleasing match may be made using any type of book, slip, random or plank matching.

Random Matching

Veneer sheets are deliberately mismatched by random selection of the pieces from one or more set of leaves. Leaves are selected without regard to colour or grain. Leaves are typically the same width across the sheet. This results in colour variations, contrasts and patterns of colour and grain. This produces a “board-like” effect. There is no discernible visual pattern on an individual sheet. There may however be patterns, sheet to sheet, that varying throughout a pack of sheets. Colour variation within a sheet may produce a barber pole effect.

Plank Matching

Plank matching is like random match. One main difference is that leaves are similar in colour but dissimilar in grain and width. Veneer leaves are specially selected and assembled in a specific order to create a planked look that simulates solid wood lamination. Veneer leaves can range in width based on selected specifications. This provides a casual rustic effect. The components may be of different widths, as well as grain with slight colour contrasts at joints. There is no discernible visual pattern on an individual sheet. There may however be a pattern sheet to sheet, but patterns change through the pack of sheets. This is the matching method used on all Decor Cabinet Company’s veneer faces. Backs of two-sided veneers will be Pleasing Match for colour and no sharp contrasts and can be Book, Slip or Random Matched.

Strips of wood veneer are called leaves. Leaves can be a variety of different widths. The widths of the leaves in the veneer you purchase can be specified with a veneer supplier. Leaves can be uniform widths or random within a veneer skin. Leaves of veneers are edge glued together to make a sheet of veneer skin. The skin is then glued to a substrate such as plywood, particleboard or MDF. Leaves can be assembled into different types of patterns. Some matching methods such as Book or Slip Matching use leaves from the same log to produce veneer skins. This results in a run of veneer skins that are very similar patterns in colour and grain. Logs however produce a limited number of leaves which will make a limited number of skins. A new log will result in a new and different pattern in colour, characteristics and grain. Other matching methods, such as Pleasing Match, are made of leaves selected primarily for colour without regard for grain and characteristics. These skins can be made from leaves of the same log or multiple logs. Random Match and Plank Matched veneer skins are made using leaves from various logs. This method can produce more skins that are similar in colour, characteristics and grain.

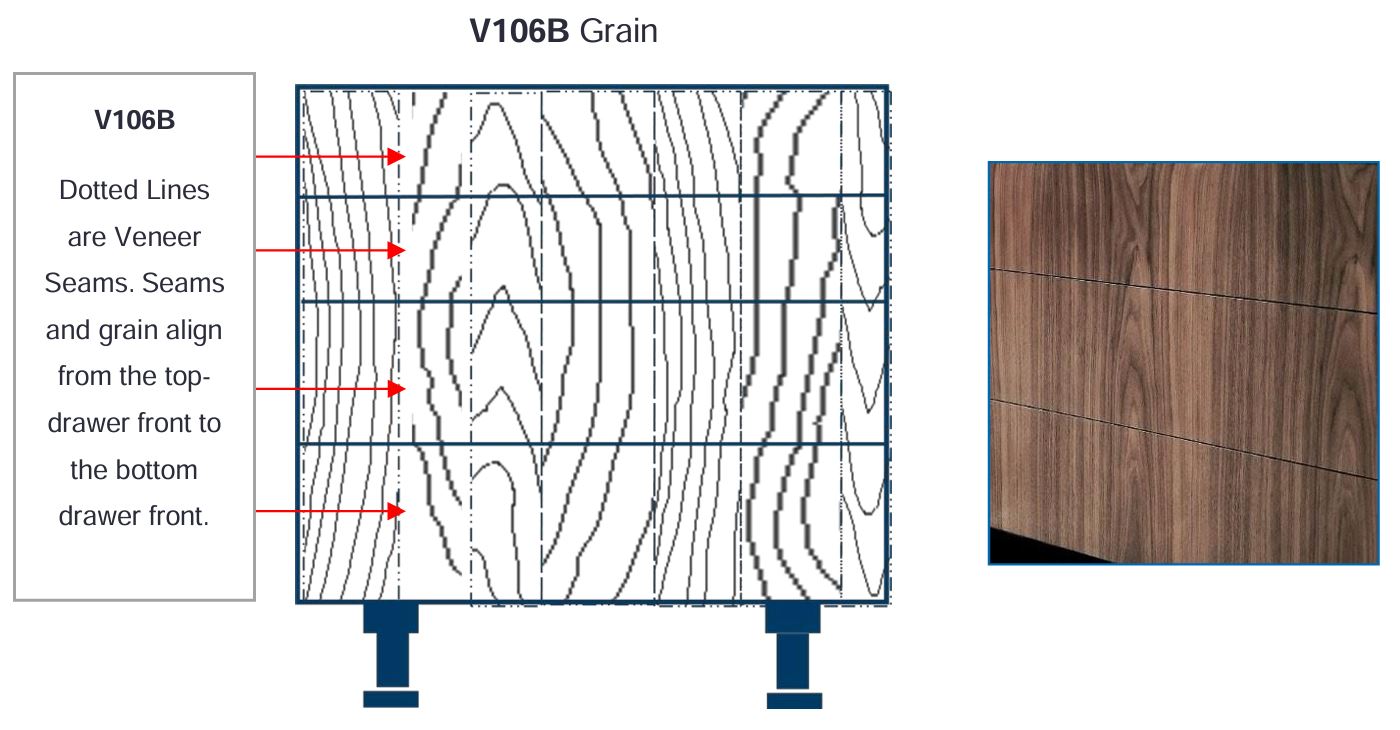

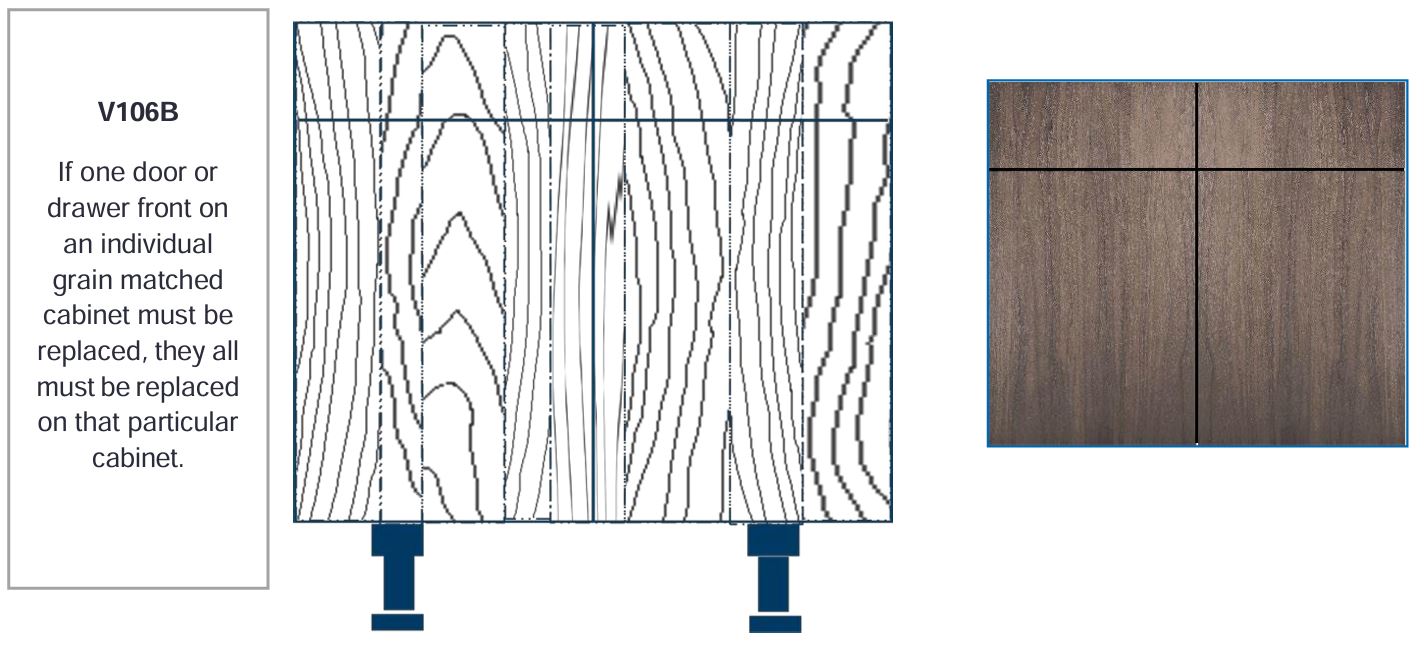

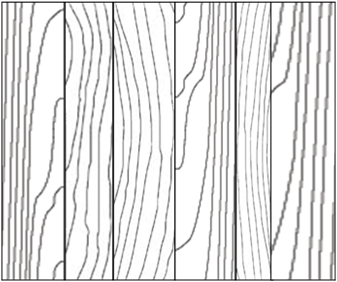

V106 Door Styles. Grain

What to expect from the V106B Door Style?

The V106B door style is a veneer, edge banded door. What does “Grain Matching” mean on this door style? “Grain Matching” means that the grain of the wood and seams of the veneer leaves on each face component are aligned vertically on each cabinet. This “Grain Matching” is on a per cabinet basis. Seams and grain will align regardless of the cabinet’s configuration. Cabinet to cabinet may vary slightly in colour and grain. See your catalogue for limitations on this door style.

“Grain Matching” is not to be confused with “Veneer Matching”. “Veneer Matching” are various methods used by veneer manufacturers to make veneer skins. Wood veneers used at Decor are Oak, Rift Oak, Maple, Clear Alder, Knotty Alder, Cherry, and Walnut. The “Veneer” Matching Method used on the face of Decor veneers is called “Plank matching”.

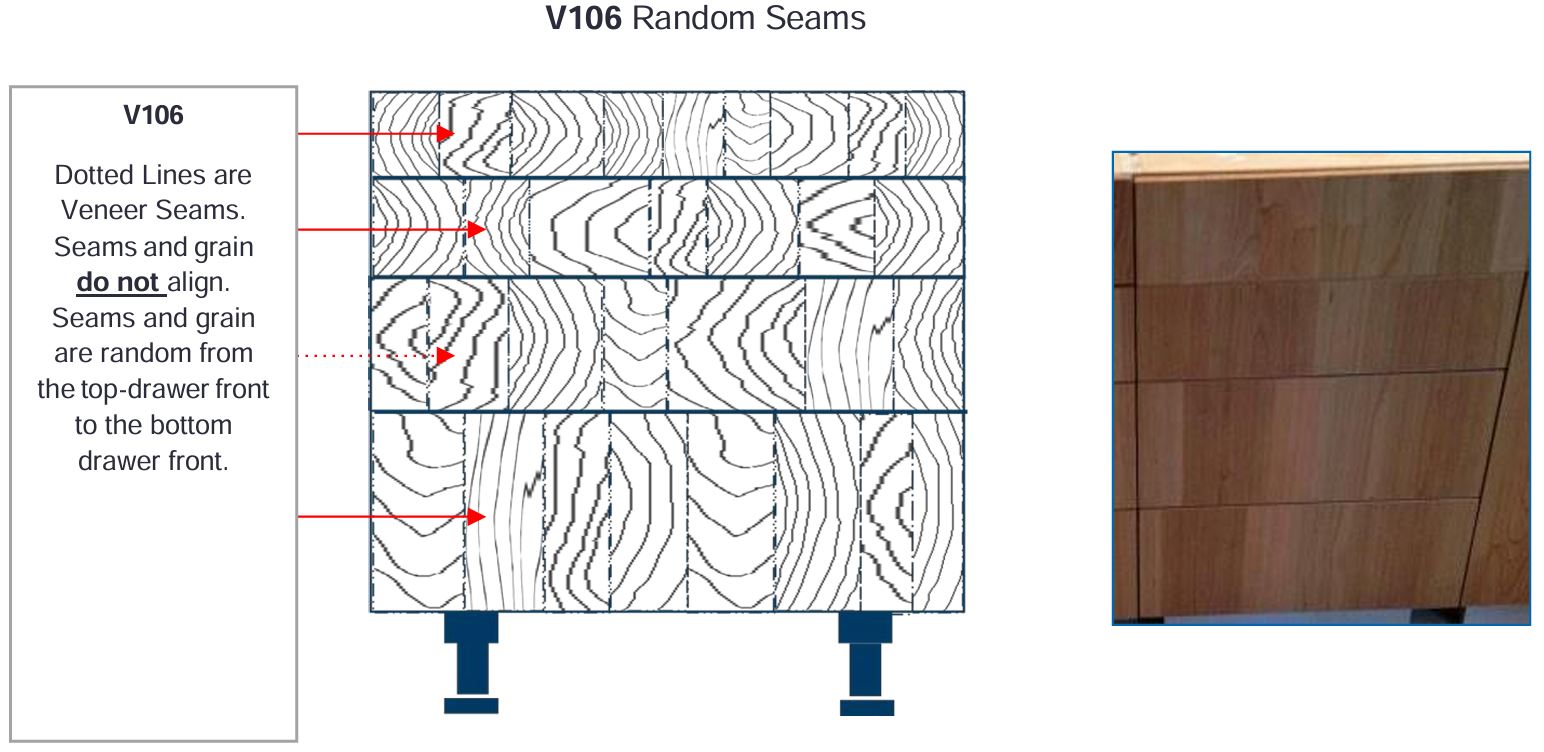

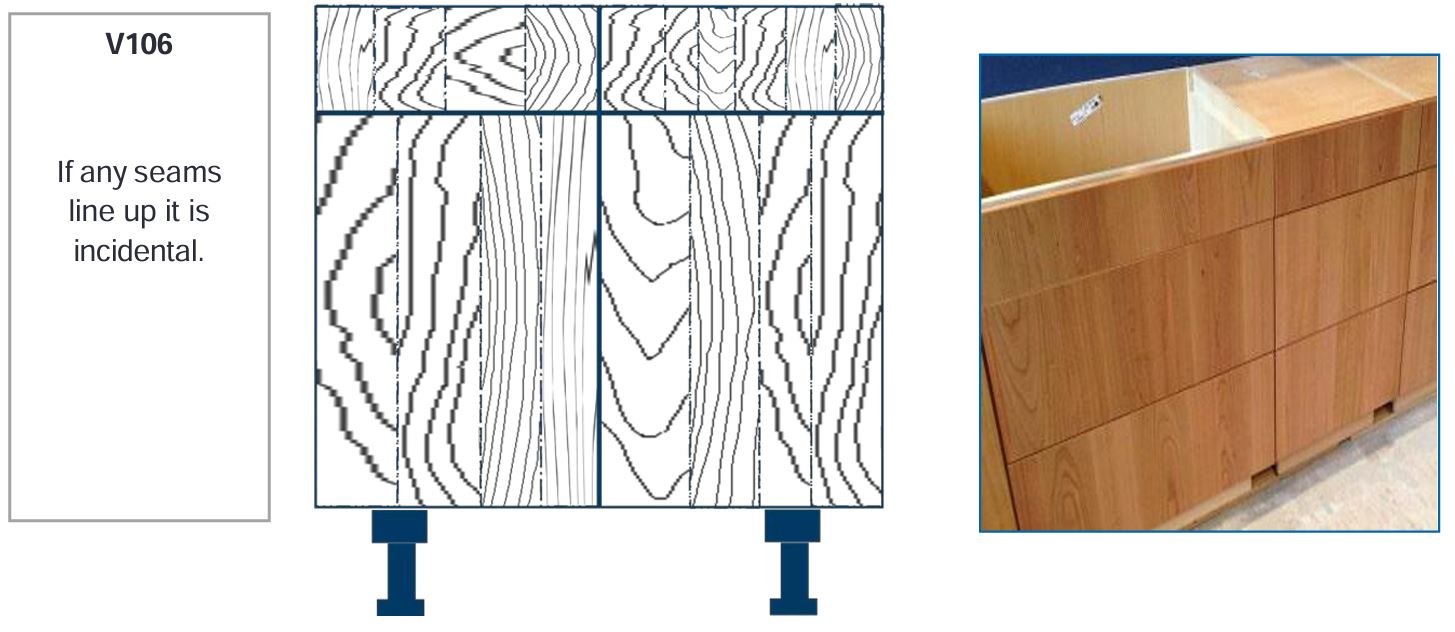

V106 Door Styles. Random Seams

What to expect from the V106 door style?

The V106 door style is a veneer, edge banded door. There is NO grain matching on this door style. Components for each cabinet are cut at random. This means that the grain of the wood and seams of the veneer of each face component will not align vertically or horizontally on each cabinet. If seams align in any way, it is incidental. Each cabinet will have random patterns. Wood veneers used at Decor are Oak, Rift Oak, Maple, Clear Alder, Knotty Alder, Cherry, and Walnut. The Veneer Matching Method used on the face of Decor veneers is called “Plank matching”. Face components on a V106 will not necessarily match on a per cabinet basis. Cabinet to cabinet may vary in colour and grain. Overall, the kitchen will have similar colour and characteristics but may have a checkerboard appearance.

Wood Defect Definitions

Maple

Worm holes

Worm holes can range in size from 1/16” to over 1/4”. These holes are generally caused by beetles when they reach maturity and exit the timber. Some prefer softwoods like pine, spruce and cedar. While others prefer hardwoods such as oak, maple, ash, and mahogany. All wood boring beetles like wood that is damp.

Maple

Worm Tracks

These marks are caused by various types of wood larvae. Often appearing as sound discolorations running with or across the grain in straight to wavy streaks. Sometimes referred to as “pith flecks” in certain species of hardwoods because of a resemblance to the colour of pith.

Maple

Mineral streaks

Mineral streaks appear in a blackish brown, green or gray colour to an olive and blackish brown colour, which typically follow the grain pattern. Mineral streaks develop when a tree absorbs and deposits minerals from the soil. Mineral streaks are a high contrast in lighter wood grains.

Cherry

Gum streaks or spots

Mineral-like streaks of colour naturally occurring only in cherry. Gum is often associated with sunken lesions on trunks called cankers as well as branches, or twigs. Cankers may be caused in a variety of ways such as, insects’ mechanical injuries, winter damage, herbicide injury, and various fungal or bacterial infections.

Maple

Crossbar

A grain irregularity resembling a dip in the grain running at right angles to the length of the veneer.

White Rift Oak

Ray Flake

The typical figuring of wood when the pith rays are cut across at an angle of 180 degrees when slicing. This is strongly pronounced, particularly in oak. They are generally considered as inferior veneers.

Heartwood and sapwood

Heartwood is the mature wood, which is often darker, extending from the sapwood to the pith. Sapwood is the lighter colored wood growing from inside the bark to the heartwood. In some species we use the heartwood and other species we use the sapwood.

Clear Alder (Veneer)

Loose Side (Veneer)

With Loose Side knife-cut veneer, it’s the side of the sheet that was in contact with the knife as the veneer was being cut that will be shown. The Loose Side contains cutting checks (lathe checks) because of the bending of the wood at the knife’s edge. The grain may appear open or pitted with more wood fiber. On stain colors these areas may appear differently as they will absorb stain differently.

Clear Alder (Veneer)

Tight Side (Veneer)

With a Tight Side knife-cut veneer, it’s the side of the sheet that was farthest from the knife as the sheet was being cut that will be shown. The Tight Side contains no cutting checks (lathe checks). Pores of the wood appear smooth and closed. Preferred side for stain finishing.

Unsound knot

An area that was once the base of a branch or twig and has a pith center. The center may be soft, showing signs of decay or parts are missing.

Knotty Alder

Open Knot

A knot that’s solid across its face, that also shows no signs of decay. An open knot is as hard as the surrounding wood but has splits or gaps but will stay in place.

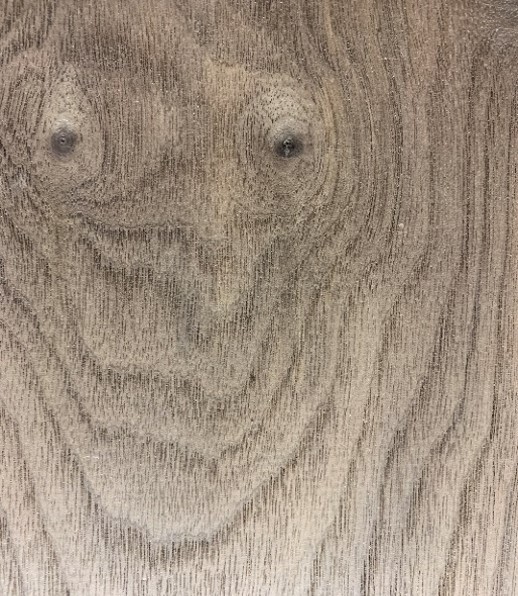

Walnut

Pin Knot

A pin knot with a dark center up to 1/8″ in diameter (in most grades) is called a conspicuous pin knot and is limited by the product standard in grades. A knot that is solid across its face, at least as hard as the surrounding wood, and shows no sign of decay.

Cherry

Burl, Conspicuous

A swirl or twist in the grain of the wood that usually occurs near a knot or crotch. It is associated with abrupt colour variation and/or cluster of small dark piths caused by adventitious buds.

Maple

Vine Marks

Vine marks are made by restrictions of growth caused by woody vines winding their way around a tree. Some vine species are such that, as the tree grows in girth, instead of breaking the vine, it grows around it. Vine marks are typically isolated, tightly compact figures, that can usually cause a winding vine to compress the normal growth pattern in that region of the tree.

Oak

Check/Cracks

A lengthwise opening on the face grain of the board resulting from rapid or faulty drying.

Oak

Bark pocket

A bark-filled distortion in the grain pattern. Bark pockets are patches or inclusions of bark partially or fully embedded in the wood.

Oak

Sound Knot

A knot that is solid across its face which shows no sign of decay. A sound knot is also as hard as the surrounding wood and is solid and free from decay. It will stay in place.

Knotty Alder

Spike Knot

A spike knot is produced when the limb is cut either lengthwise or diagonally.

Maple

Bird's Eye

Birds Eye is a type of figure that occurs within several kinds of wood, most notably in hard maple. It has a distinctive pattern that resembles tiny, swirling eyes disrupting the smooth lines of grain. It is somewhat like burl, but it is quite different: the small knots that make the burl are missing.

Maple

Decay or rot

The breaking down of the wood substance by fungi. The discoloration of the sapwood indicates the initial evidence of decay.

Maple

Discolorations

Colour variations in the wood or veneer. Common stains are sap stains, blue stains, stain produced by chemical reactions between the iron of the cutting knife and the tannic acid of the wood. Others are caused by exposure of natural wood extractives to oxygen and light, to chemical action of vat treatments or the adhesive components, and/or to the surface finish.